Print on rigid materials

The flexibility of UV printers is exceptional, practically being able to print on almost any type of rigid material with a thickness of up to 5.08 cm, such as:

- Paper and Cardboard - WAVE CARDBOARDS, GC CARDBOARDS, DUPLEX CARDBOARDS,

- SPECIAL CARTONS, etc.;

- PVC & PVC derivatives - FOREX, FOAM, DISPA, STADUR, PLEXIGLASS, KAPP, ACRYLIC, POLYCARBONATE, etc;

- Wood & wood derivatives - HDF, MDF, chipboard, HPL, etc;

- Metal & metal derivatives - ALUBOND;

- GLASS.

As simple and obvious as it may seem in the current technological context, personalization by digital printing on rigid materials is another challenge for the printing industry. In principle, digital UV ink printers, especially high-end ones, can print on any rigid and flexible material in the roll. However, for new materials or those that are not intended for the advertising production industry, various tests must be performed with various primer solutions, so as to create an optimal adhesive surface for UV ink.

The UV print on rigid materials is made with the help of the latest generation Fuji Acujity HS true flatbed printer, installed in 2019 (UV printer link details here). A DURST P5 350 hybrid digital printer will also be installed, which will be able to print on rigid plates with widths up to 350 cm and unlimited lengths, as well as the dimensions of the plates used.

Color processing in the process of UV printing on rigid materials is made Software Caldera GrandRip +, dedicated to large format applications, which ensures good productivity, correct and accurate color reproduction, according to FOGRA standards. Fast, flexible and strong.

Print on rigid materials - Finishes

The simple print on rigid materials cannot have the expected marketing effect if it is not transformed by various finishes, into the final products of trade marketing and promotion. The state-of-the-art digital finishing table (launched at DRUPA 2016) produced by the world leader in the ESKO profile industry, also ensures exceptional versatility due to the possibility of attaching various tools for each type of material. Thus, materials such as Corrugated Cardboard, PVC and other plastic derivatives, Wood, Metal, Leather, etc. can be cut and finished. As an example, the optional Psaligraphy tool allows the realization of very fine details and high precision cuts. A new multifunctional table is to be installed, which will also have high-power cutters, so that the edges for very hard materials can be cut out of contour and finished. The digital finishing table will have 2 axles with 2 motor groups that will work in tandem to double the working speed and a usable area of 210x320 cm, which will allow the finishing of prints made on large rigid materials in a very short time.

The simple print on rigid materials cannot have the expected marketing effect if it is not transformed by various finishes, into the final products of trade marketing and promotion. The state-of-the-art digital finishing table (launched at DRUPA 2016) produced by the world leader in the ESKO profile industry, also ensures exceptional versatility due to the possibility of attaching various tools for each type of material. Thus, materials such as Corrugated Cardboard, PVC and other plastic derivatives, Wood, Metal, Leather, etc. can be cut and finished. As an example, the optional Psaligraphy tool allows the realization of very fine details and high precision cuts. A new multifunctional table is to be installed, which will also have high-power cutters, so that the edges for very hard materials can be cut out of contour and finished. The digital finishing table will have 2 axles with 2 motor groups that will work in tandem to double the working speed and a usable area of 210x320 cm, which will allow the finishing of prints made on large rigid materials in a very short time.

Prices are calculated according to the complexity of the work, for an average complexity the price of cutting and finishing is 4 euro + VAT / sqm

Print on rigid materials - Applications

The applications are multiple, the digital print on rigid materials being commonly used for making products such as:

The applications are multiple, the digital print on rigid materials being commonly used for making products such as:

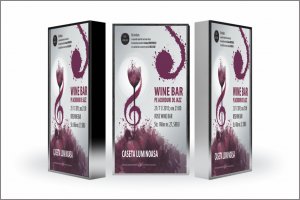

- POSM DISPLAY - Point of Sales Material used especially in the retail industry, for the promotion of products in supermarkets.

- CARDBOARD PACKAGING & CUSTOM BOXES - product packaging made of various types of cardboard (GC, duplex, etc.) and collective or product boxes made of corrugated cardboard.

- ADVERTISING & SIGNAL PRODUCTION PRODUCTS for promoting your company in various events or campaigns to promote your products.

- DISPLAY SYSTEMS for indoor or outdoor promotion.

The print on rigid materials has frequent applications in the industrial area, being possible applications such as: - PRINT ON GLASS - in the interior design and commercial space industry;

- PRINT ON WOOD, MDF, HDF, PAL - in the furniture industry;

- PRINT ON METAL - in the automotive industry or in the production of household appliances;

- PRINT ON LEATHER - in the industry of products made of natural or ecological leather;

- PRINT ON PLEXIGLASS - in the protection and advertising industry;

- PRINT ON FOREX AND OTHER MATERIALS DERIVED FROM PVC - in the retail industry.

In conclusion, what would be the easiest to remember is the possibility to print on any type of rigid or flexible material, regardless of whether we are talking about the advertising production industry or other industries such as the glass, furniture or leather industry.

Print certifications on rigid materials:

FOGRA - represents not only a guarantee of the quality, but also a confirmation of the technical level and know-how of the production process used. Exact reproduction of Pantone colors according to brand identity is one of the main challenges of the printing industry, especially for large digital printing. In order to obtain the best results in this sense, it is necessary to strictly observe all the requirements in the design stages, printing on rigid materials and quality control, but last but not least, the latest technology printing equipment.

FOGRA certification can guarantee more than any other commitment, the implementation of the most demanding requirements throughout the printing process on rigid materials, so as to obtain a correct and constant colorimetry throughout the entire circulation and very important from one work to another. Thus, the correct and constant reproduction of PANTONE colors can be guaranteed, such an important aspect for all companies that want to respect the brand colors on all materials, depending on their characteristics and colors. For the correct reproduction of the colors on colored materials in the mass will be applied 1 or 2 white layers on the whole surface to be printed.

Obtaining in 2019 the most coveted certification in the printing industry worldwide, is the best proof of good practices, as a guarantee of quality and last but not least as a confirmation of the capacity of our technical equipment. FOGRA certification itself represents for any company in the digital printing industry, enrolling in the most demanding exam, passing it and thus obtaining the guarantee that it can be able to do exactly what it claims it can do.

FOGRA certification details here: http://www.tipografia-global-print.ro/certificare-fogra-certificare-pantone-more/

PANTONE - to reproduce and design in the most realistic way the PANTONE and brand colors.

FSC - for certain types of cartons for which there is traceability of the raw material.

The objective for each print project on rigid materials entrusted by our clients, is to increase the visibility of the brand and of the product to be promoted. If we can consider that it is no longer enough just to make ourselves heard, then we must certainly make ourselves better seen!

File Upload

max. 25 mb